Rielec’s Clus MOT Station Automates Shipment Verification

Rielec has designed the Clus MOT RFID tunnel solution, featuring the Impinj R700 RAIN RFID reader, to bring speed and accuracy to bulk fulfillment and shipping processes.

RAIN RFID tunnel solution drives greater efficiency and accuracy through distribution

In retail, speed and accuracy in distribution centers are essential to success. Shipping errors are not only costly but can erode supplier and customer confidence in a company. Many of the problems retailers face come from outdated, labor-intensive, manual inventory and shipping processes that can be time-consuming and subject to error.

Without efficient verification, shipments can be incomplete or inaccurate, or orders can go to the wrong locations. In addition to driving down customer satisfaction, such errors come with the costs of returning and replacing products. Shipping errors can hinder omnichannel fulfillment, where success depends on the speed and accuracy achieved when filling customers’ orders.

RAIN RFID tunnel automates and validates picks, packs, and shipments

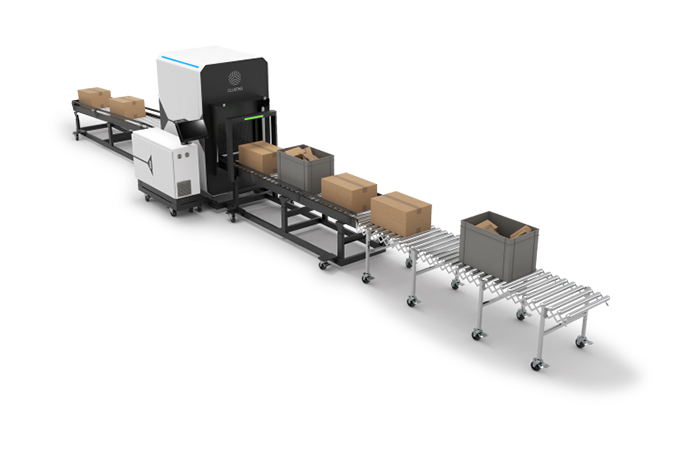

The Clus MOT Station, from Impinj gold-level partner Rielec, automates what were once slow, tedious tasks — saving time and money by automating shipment verification and receiving, and increasing process throughput. The MOT (Multi-Operations Tunnel) Station is powered by Impinj R700 RAIN RFID readers and is designed to scan RFID-tagged cartons, totes, and packages for shipping and receiving in distribution centers, identifying item-level contents with up to 100% accuracy.

The station scans RFID-tagged cartons and manages the item contents in bulk as they pass through the tunnel on conveyor belts. As cartons are read and the items are validated against shipment orders, variations are reported, and the carton is rerouted for reconciliation. Bulk validation with the tunnel can be installed at various points along the distribution process, after orders are picked, items are packed, or where shipment audits are to be performed if needed.

Using RAIN RFID, the tunnel system can read and validate the item contents of boxes — up to 400 tags per box at speeds of up to 1,400 boxes per hour, or up to 560,000 tags per hour. In addition, the Clus MOT Station was designed as a small footprint tunnel, allowing it to be installed in spaces with strict space limitations. It was also developed with an integrated shield to contain the RFID frequency signal, helping prevent cross-reading and unwanted external readings, ensuring data accuracy.

Clus MOT Station delivers improved accuracy, efficiency, cost savings, and customer satisfaction

- Powered by the Impinj R700 reader, the solution improves shipping accuracy up to 100%

- Increases speed and accuracy of order fulfillment, reducing operating time by up to 40% and increasing carton throughput

- Reads and rejects inaccurate cartons to divert them to auditing areas where the errors will be reconciled

- Provides an audit trail, eliminating unaccounted-for losses in warehouses and distribution centers

- Integrates easily with any type of conveyor system, allowing for customized configurations

- Delivers additional cost savings with lower return rates previously caused by errors in order preparation

- Improves customer experience as shipment errors from the distribution center are eliminated, delivery time is reduced, and accuracy is increased

RAIN RFID is used to track carton data points throughout distribution centers, to optimize procedures and operations anywhere along the process. Because of this, the Clus MOT Station tunnel can be installed to perform tote content verification during intermediate processes such as batch picking. Using RAIN RFID to verify totes following manual picking, for example, will reduce the occurrence of totes with missing units getting to packing stations, which causes a costly, time-consuming halt in operations.

Tuesday, July 26, 2022

ABOUT THE PARTNER

Rielec

The Rielec Group is a Spain-based group of companies concerned with logistics automation and RFID solutions. Clustag is the Rielec Group company that develops RFID solutions for major retailers and suppliers.

Sign Up for the latest news

Join thousands of people and subscribe to get the latest industry happenings delivered straight to your inbox.

Impinj products deliver connectivity for this solution

Tag Chips

Impinj RAIN RFID tag chips provide unique identifiers and enable smart, connected things (endpoints)

Learn more

Readers

Impinj RAIN RFID readers are smart edge devices that identify and locate connected things

Learn more